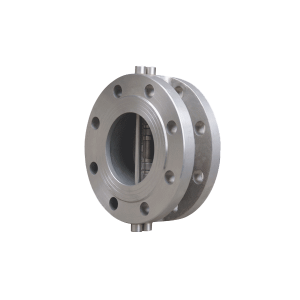

C95800 Wafer Type Check Valve

Features

1. Small in size, light in weight, compact in structure, easy in maintenance.

2. Two torsion springs are used excreting on each of the pair valve plates. Which close the plates quickly and automatically.

3. The quick-close action prevents the medium from flowing back and eliminates water-hammer effect.

4. This valve is short in length, so that it is rigid and easy to mount.

5. It is easy to install on pipeline which is laid horizontally or vertically.

6. This valve is tightly sealed without leakage under the pressure water test.

7. Safe and reliable in operation, high interference-resistance.

8. The connection dimensions of flanges accord with the standards of GB4216-84 GB4216.84

9. The face to face dimensions are in accordance with GB12221-89, ISO5752-82. The stem of the valve should be perpendicular to the horizontal level when the valve is mounted on horizontal pipeline. For vertical installation the direction of flow should be downward.

10. Wafer ends, available with flanged ends, Welco Valve can also produce the size up to 56" and the pressure will be higher than Class 600.

Installation of check valve

Do you really know the installation position of the check valve? How to determine the installation position of the check valve? What is the difference between the check valve installed in front of the pump and the check valve installed behind the pump? Where is the check valve installed in front of the pump applicable? Check valves are usually used together with other valves. Where should check valves be installed when they are used together with other valves? Daejeon valve will help you.

The check valve, also known as the check valve, is an automatic valve. It relies on the pressure of the flowing medium in the pipeline to push the valve disc to close and open the valve. When the medium stops flowing, the check valve disc closes, and it can prevent the backflow of the medium in the pipeline, which plays a great role in ensuring the safety of the pipeline. The check valve is installed to ensure the flow direction inside the water pump, so as to ensure the normal operation of the water pump. Therefore, the installation position of the check valve can be divided into two situations: whether it is installed in front of or behind the water pump. One is installed at the end of the vertical suction pipe in front of the water pump, so as to fill the water pump without pumping primary water, Because there is no water in the pump and the suction pipe in front of the pump, the pump can only idle and can not pump water, so the pump must be filled with water to pump water. The installation of this kind of pump is a method when it is higher than the liquid level, which is also called negative pressure method, such as pumping water from the well. Another installation method of water pump is that the liquid level is higher than the water pump. Generally, this method is used for secondary water supply. Because the liquid level is higher than the water pump, the water outlet valve of the water pump does not need to be closed when starting and stopping the water pump, so the check valve should be installed behind the water pump.